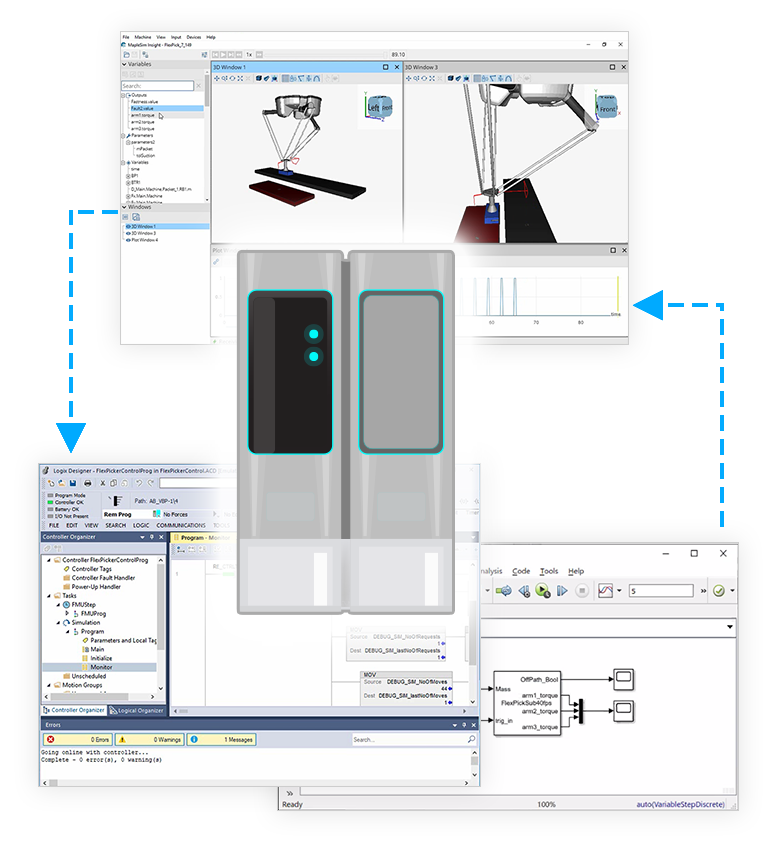

With the latest software from Maplesoft and Rockwell Automation, digital

twin technology can be integrated with the control software development

process, making virtual commissioning a realistic technique for automation

companies to adopt today. There is now a simplified workflow between

the system-level modeling environment (MapleSim)and the automation

design environment (Studio 5000). This allows designers to create their

digital models and test their PLC code in the same workflow, providing

valuable feedback during the design phase where changes are easier and

less expensive to implement.

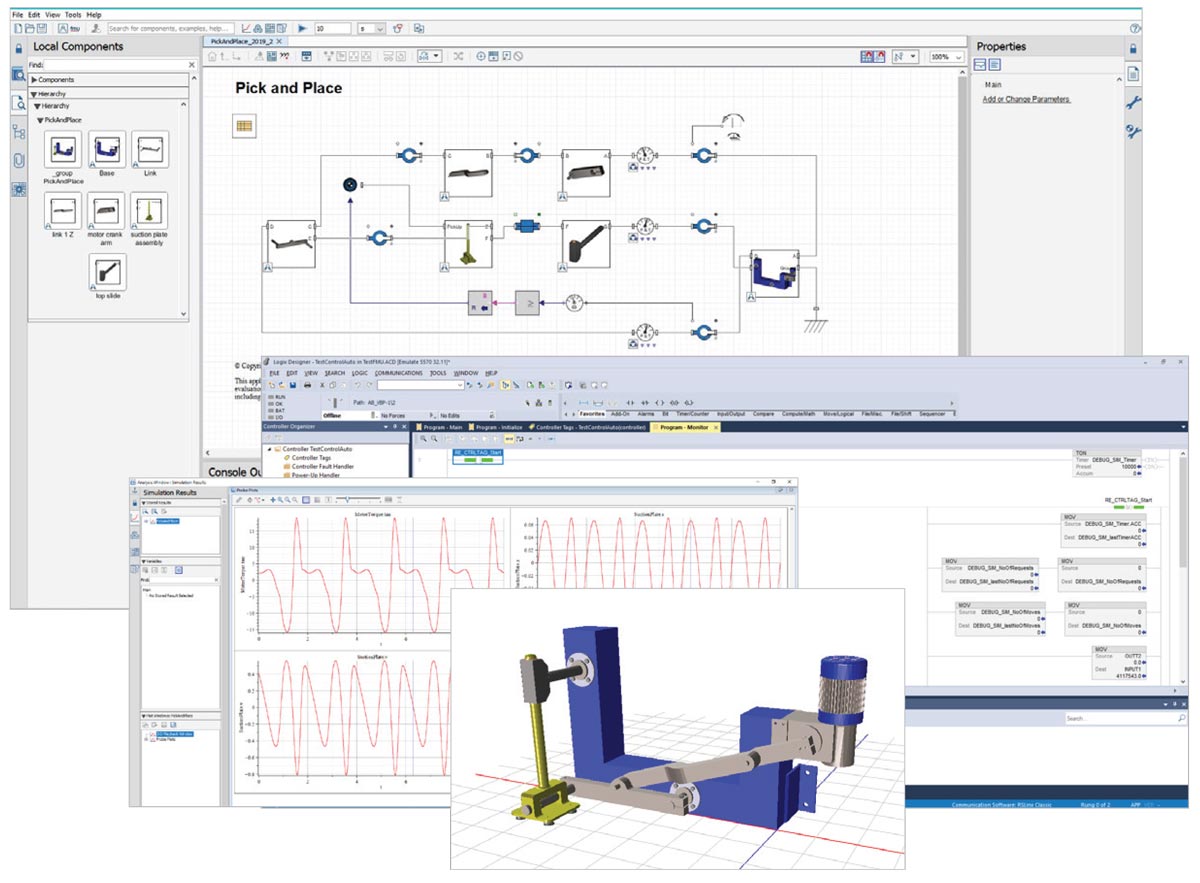

The MapleSim Virtual Commissioning Workflow:

- Quickly create a digital model by leveraging previous CAD data for use in both MapleSim and Studio 5000.

- Get your machine design right before prototyping

- Test your control software before connecting it to a physical machine

- Visually debug your machine software by seeing the mechanism’s response to your control code

- No guessing with effective inertias and approximated accelerations – directly export a model’s forces/torques to Motion Analyzer

Use MapleSim in your next project:

Rapid creation and testing of initial concepts

By enabling quick prototyping and testing of design concepts, MapleSim allows you to try out more ideas in less time, getting you on track quickly.

High fidelity models

MapleSim produces high fidelity, computationally efficient models suitable for in-the-loop simulations, controller design, and activities such as optimization, sensitivity analysis, and what-if scenarios.

Efficient use of digital twins

MapleSim offers two streamlined export functions for efficient use of digital twins in the development process. First, a model’s simulation data can be exported in a format directly readable by Motion Analyzer, allowing it to “right-size” the servo drives, motors and gearboxes. Secondly, the model itself can be exported to Studio 5000 for control code testing.

Commission with confidence

Once linked to Studio 5000, the controller code can be tested against the model before a physical prototype has been created. The result is hardware-in-the-loop simulation, where the machine's behavior is emulated in real time to create a controlled environment. The behavior of the digital model can then be visualized live within MapleSim.